Ukuhanjiswa komatshini okuguquguqukayo, umsebenzi omncinci ongenamsebenzi osetyenzisiweyo kwinkqubo yokuhanjiswa kwamandla, ngcono umphumo wokonga amandla.Kwinkqubo yokuhanjiswa kwamandla ebhanti eqhelekileyo yebhanti, ubunzima bomzimba webhanti, indawo esongelwe kwidayamitha yevili kunye nolwandiso olusisigxina lwamandla lumisela ukusetyenziswa kwamandla omzimba webhanti xa usenza umsebenzi.Ke ngoko, ukukhethwa kunye nokucwangciswa kwebhanti lokuhambisa kwisixhobo yinto ephambili yokwandisa ukonga amandla, kunye nebhanti lokuhambisa elinobude obusisigxina, umzimba webhanti elithambileyo kunye nokungqubana komphezulu ophakathi lolona khetho lungcono kubathengi.Ibhanti le-polyester drive lika-Annilte liyasombulula ezi ngxaki zingasentla kakuhle.

1. Ipolyester eneempawu zokonga amandla

a) Amandla aphezulu kunye noxinzelelo oluzinzileyo.

Ngokuqhelekileyo, xa kuthelekiswa ne-substrate, i-1% yamandla e-fixed stretch belt yebhanti ye-polyester i-30% ukuya kwi-50% ephezulu, oku kuthetha ukuba ibhanti ayifuni ukulungelelanisa ukuxhatshazwa ngokuphindaphindiweyo emva kokulungelelanisa amandla okuxhatshazwa.Ukongezelela, ukusebenza kwayo kakuhle, ukunyanzeliswa okuphakathi kwaye akulula ukulahlekelwa yisantya, ukwenzela ukuba umthwalo wokuthwala uyancipha, ngaloo ndlela ugcina ukusetyenziswa kombane.

b) Imitya ilula ngobunzima

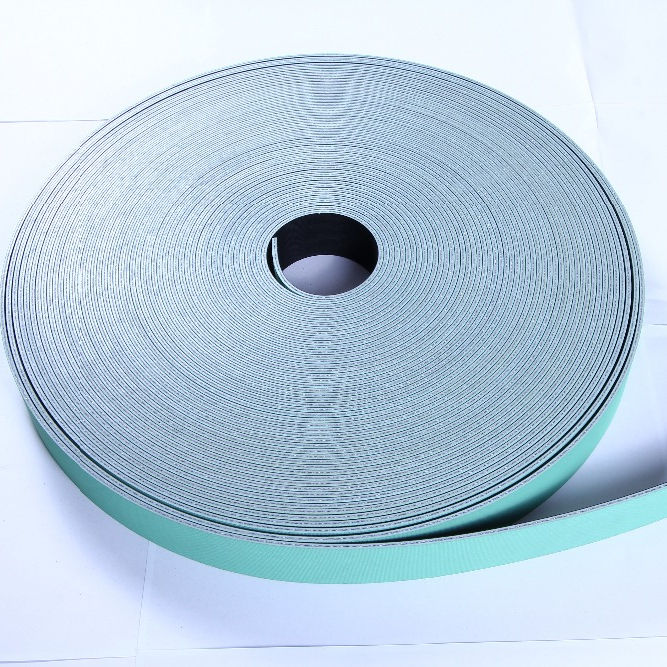

Umaleko owomeleleyo webhanti yepolyester sisakhiwo esikhethekileyo selaphu le-polyester elisezantsi-amandla aphezulu, xa ukuhanjiswa kwamandla afanayo, ungakhetha ibhanti elincinci elincinci, ukuze unciphise umzuzu we-inertia kunye ne-centrifugal yamandla ebhanti elicaba. , ukwenzela ukuba ukusetyenziswa kwayo kwamandla kuncitshiswe kwaye ukusetyenziswa kombane kugcinwe.

c) Ukuba bhetyebhetye okulungileyo

Ngenxa yokuba umzimba webhanti le-polyester uthambile, umzimba webhanti kunye nevili lebhanti usongelwe kakuhle, uxinzelelo lokugoba luyancitshiswa, ukusebenza kakuhle kokuhanjiswa kuphuculwe kwaye nokusetyenziswa kwamandla kugcinwa kancinci.

d) Isidibanisi siyakhawuleza kwaye sinobuhlobo nokusingqongileyo

Umdibaniso wamkela ibhondi yamazinyo ashushu anyibilikayo emzimbeni we-thermoplastic elastomer, akukho nto incamathelayo isetyenziswayo, kwaye ukusebenza akukhawulelwanga kwicala, ngoko ke ixesha lofakelo liyagcinwa kwaye ukungcoliseka kwendalo kuncitshisiwe.

2. Isiphumo sokugcina amandla

Uvavanyo lothelekiso lwentsimi lubonisa ukuba umyinge wogcino lwamandla womtya wepolyester ungaphezulu kwe-10% kunolo lwe-baseband yetshiphu yasekhaya neyangaphandle.

Ugcino lwamandla ebhanti lepolyester lubaluleke kakhulu, kumatshini wokugquma umsonto, izinga lokonga amandla linokufikelela kuma-20%, kumatshini omfutshane wokujija ifayibha kabini, izinga lokonga amandla lingaphezulu kwe-15%, kumatshini wokujija amaxesha angama-310. , izinga lokonga amandla li-10%.Ke ngoko, ibhanti lepolyester elinomsebenzi walo ogqwesileyo wokonga amandla, lisetyenziswe ngokubanzi njengebhanti ledragoni kunye nebhanti lamandla lezixhobo ezitsha ezinesantya esiphezulu ezinjengomatshini wokugquma, umatshini omde ojikelezayo, umatshini wokujikeleza kunye nomatshini wokujija kabini.

3. Uthelekiso lwentsebenzo yesakhiwo

Ibhanti le-polyester lenziwe ngerabha ekhethekileyo ye-carboxyl nitrile butadiene njengeyona nto iphambili yokuqhubela phambili kunye ne-friction layer, kwaye ukusebenza kufana ne-substrate.

Iphepha le-thermoplastic polymer elastomer lisetyenziswa njengomaleko wenguqu odibeneyo.Emva kokumisa, iinqununu ze-polymer ze-thermoplastic ziyancibilika kwaye zikhutshwe yi-extruder ukuze zenze iphepha kunye nobukhulu obufanayo kunye nobubanzi be-1200mm.Kwaye ngokobunzima obahlukeneyo bomzimba webhanti 0.3 ~ 1.2mm ubukhulu obuhlukeneyo beemveliso zeshiti.Izinto eziphathekayo zineempawu ze-elasticity egqwesileyo, ukuxhathisa i-oyile, ukuxhathisa ubushushu, ukuxhathisa ukukhathala, ukuguquguquka, ubunzima obuncinane obuthile kunye nobunzima obulula, kwaye ineempawu ezintle zokudibanisa ezinomaleko oqinileyo kunye nerabha.

Ixesha lokuposa: Nov-30-2023